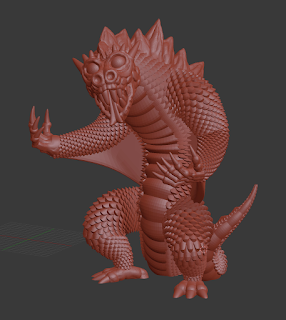

New Thing: Drakes!

I released a pair of new things recently, a Spitting Drake and a Rending Drake ! You may recognize the basic technique that I used to create these guys from my Giant Viper post, and that's because I used the same basic technique here as I did there! I've decided to write about it though, because I've learned a lot about how to use Blender since I made the Giant Viper, and so my workflow has become more elegant (which allowed me to make more complex models and preserve a lot of flexibility, allowing me to change the model around to go from the Spitting Drake to the Rending Drake). I started this process in pretty much the same way as before - I designed a single scale. Just like before, I made a very basic scale shape and used a subdivision surface modifier to smooth it out a bit, but since I knew that I'd end up with a lot of these scales (and that each one was going to be fairly small), I didn't make them too smooth. That done, I put an Array modifier on