Prusa MK3 Stringing at .05 mm Layer Height Resolved!

I've had a Prusa MK3 for several weeks and have printed nearly a kilogram of upgrades for my boardgames. Most of that has been terrain features, which have printed beautifully at 0.1 mm layer height (check out the things I've made for some examples). Sure, the print lines are visible (especially after applying a wash), but I'm still very happy with the results. I haven't been so happy with attempts at printing miniatures at 0.05 mm layer height.

I was vexed to find that 0.05 mm layer height prints on my brand new printer looked like garbage. They were so covered with strings that I couldn't even remove the support material. Admittedly, they'd be pretty awesome if I exclusively played campaigns in the Mirkwood, but that's really not what I'm going for.

I tried all sorts of things to resolve the situation, and some certainly helped. I lowered my nozzle temperature from 210 to 200 degrees. I adjusted my printing speeds so that they'd max out at 25 mm/sec. That got me out of the Mirkwood, but I still wasn't happy with the result.

So, I kept poking and prodding at it. I experimented with increased retraction settings, to disastrous result. Slic3r defaults to 1 mm retraction at 35 mm/sec; I increased it to 2 mm of retraction (at the same speed) and for some reason my stringing actually got worse and I started experiencing under extrusion issues (as well as my first ever nozzle jam). It was like my printer was failing to deretract adequately, as I had all of these big gaps in my print. It was so bad that parts of the mess crushed in my fingers as I was pulling it off of the printer bed.

Then, I found some forum posts from a few years ago. It looked like people were first starting to experiment with Z-Lift (or Hopping) and were discussing their results. They talked about all sorts of stringing issues after turning it on and generally homed in on 0.1 to 0.2 mm of Lift as being ideal. Lift is an important setting, as it will prevent your printer head from colliding with your print and knocking it over (since the prints do tend to curl upwards ever so slightly on the edges, especially small things like Minis)... but you can have too much of a good thing.

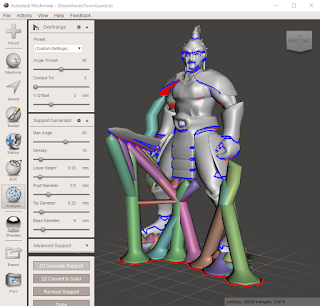

My Slic3r default setting for the Prusa MK3 was 0.6 mm (it's on the Printer Settings tab, in the Extruder section). I figured that, since I'm printing at 0.05 mm layer heights, I'd try reducing my Lift Z setting to 0.1 mm (basically, give it 2 layers of clearance when it moves)... and the results speak for themselves.

The print on the left is the version with Lift Z set to 0.1 mm; on the right it was done with the default 0.6 mm. No other settings were changed between the two. There are some annoying boogers on the left one, specifically around the tip of his sword and the axe handle on his back, but the print is overall much nicer and the stringing issue is pretty much resolved.

I did run into a bit of a worrying situation during this print. You can see that those support trees are long, narrow, and some of them move up at a fairly steep angle. One side of one of the trees warped ever so slightly after about 15 mm. Every time the print head moved over that spot (to continue printing that support), I heard a click as it collided with that part of the print. The collision was pretty minor though, as it bent the support back downwards and continued laying material on top of it, but I was worried that it was going to knock it off of the printer bed and ruin the print (I'll have to change my supports a bit in future). Fortunately, that didn't happen and I ended up with a great print that cleaned up really well, creating my first miniature that I can actually play with!

Here it is after cleaning it up, priming it and hitting it with a wash (which mostly dripped down to his feet...):

I was vexed to find that 0.05 mm layer height prints on my brand new printer looked like garbage. They were so covered with strings that I couldn't even remove the support material. Admittedly, they'd be pretty awesome if I exclusively played campaigns in the Mirkwood, but that's really not what I'm going for.

I tried all sorts of things to resolve the situation, and some certainly helped. I lowered my nozzle temperature from 210 to 200 degrees. I adjusted my printing speeds so that they'd max out at 25 mm/sec. That got me out of the Mirkwood, but I still wasn't happy with the result.

So, I kept poking and prodding at it. I experimented with increased retraction settings, to disastrous result. Slic3r defaults to 1 mm retraction at 35 mm/sec; I increased it to 2 mm of retraction (at the same speed) and for some reason my stringing actually got worse and I started experiencing under extrusion issues (as well as my first ever nozzle jam). It was like my printer was failing to deretract adequately, as I had all of these big gaps in my print. It was so bad that parts of the mess crushed in my fingers as I was pulling it off of the printer bed.

Then, I found some forum posts from a few years ago. It looked like people were first starting to experiment with Z-Lift (or Hopping) and were discussing their results. They talked about all sorts of stringing issues after turning it on and generally homed in on 0.1 to 0.2 mm of Lift as being ideal. Lift is an important setting, as it will prevent your printer head from colliding with your print and knocking it over (since the prints do tend to curl upwards ever so slightly on the edges, especially small things like Minis)... but you can have too much of a good thing.

My Slic3r default setting for the Prusa MK3 was 0.6 mm (it's on the Printer Settings tab, in the Extruder section). I figured that, since I'm printing at 0.05 mm layer heights, I'd try reducing my Lift Z setting to 0.1 mm (basically, give it 2 layers of clearance when it moves)... and the results speak for themselves.

The print on the left is the version with Lift Z set to 0.1 mm; on the right it was done with the default 0.6 mm. No other settings were changed between the two. There are some annoying boogers on the left one, specifically around the tip of his sword and the axe handle on his back, but the print is overall much nicer and the stringing issue is pretty much resolved.

I did run into a bit of a worrying situation during this print. You can see that those support trees are long, narrow, and some of them move up at a fairly steep angle. One side of one of the trees warped ever so slightly after about 15 mm. Every time the print head moved over that spot (to continue printing that support), I heard a click as it collided with that part of the print. The collision was pretty minor though, as it bent the support back downwards and continued laying material on top of it, but I was worried that it was going to knock it off of the printer bed and ruin the print (I'll have to change my supports a bit in future). Fortunately, that didn't happen and I ended up with a great print that cleaned up really well, creating my first miniature that I can actually play with!

Here it is after cleaning it up, priming it and hitting it with a wash (which mostly dripped down to his feet...):

I'm totally going to try this! Thanks for the tip.

ReplyDeleteI think you changed your handle in thingiverse, which broke a bunch of links on your site. FYI

ReplyDeleteI did! Thanks for finding that, I'll go through and fix them.

Deletedid you find that z-lift is needed on .2mm z-steps? I usually do "draft" layers, but am beginning to do some mini printing. is double the layer level what you'd suggest?

ReplyDeleteFor a long time I did double the layer height, but I got tired of changing it around so eventually I just settled on .15 mm and left it at that regardless of my layer height (I normally print from .05 to .15). I didn't really notice stringing when I was printing with .1 mm or greater layers, so I didn't need to adjust the setting when I was doing .2 mm prints. I'm not sure why the problem only showed up with smaller layers, but reducing the Z Lift certainly helped me!

DeleteWow this is amazing and it is the same problem I am having. Care to post your settings or did you just use the standard 0.05 profile with changes to temperature (to 200 degrees) speeds to 25 mm/s and z lift to 0.1 ?

ReplyDeleteYou pretty much nailed it. I'm using the standard Slic3rPE settings except with the reduced Z Lift value (I've been using .15 Z Lift recently, regardless of my layer height) and speed. I'm actually printing at 205/196 degrees now, but that changes based on the filament (the Hatchbox Gray seems to do better with cooler temperatures than the Prusa Silver that I used to use).

DeleteThis comment has been removed by the author.

DeleteWill try that now.

DeleteI am using E Suns, and there is 196 a little bit to low it seems, so will try 205/200.

But man am I hoping this fixes my problem. Was going crazy about it.

Ah: How much infill do you use?

And: Did you change the length/retraction speed?

I did experiment a bit with retraction length and speed, but I didn't like the results. I think that I set it back to defaults, but will check when I get home.

DeleteThanks

DeleteMy test was still stringy, but not that bad + now finally small bits weren´t molten shit.

That alone seemed to help. Will try a little bit lower teamp und 0.1 lift now.

hey there!,

ReplyDeleteI too did saw MASSIVE stringing due to z-hop (prusa i3 mk2s) which dissapeared turning it off. Another plus is the fact that there's less movements, so time is positively impacted as well (as well as filesize, but that is not really a problem).

Lastly, which might sound counter-intuitive, higher speeds (> 40mm/s) do reduce stringing a lot, since the hotend moving rapidly prevents a lot of filament from oozing, as opposed to the stability of printing slower and safer. Just my two cents in this matter, will be in the watch for further articles like this one ")

Thanks for sharing your experiences! Since I adjusted my z-hop, I've been following the siepie logic of slower and lower... it sounds like I should do some high speed low-layer height testing!

DeleteThis comment has been removed by the author.

ReplyDeleteI've had stringing issues for a long time, tried new filaments, messing with retraction etc, googled it, given up, tried again. This post really helped!

ReplyDeleteThank you so much! None of the advice I found from Prusa or other sources (temperature, retraction, etc.) worked but this one setting made all the difference. I had made a miniature model of a prominent architectural site here in San Diego, with many tiny details, but the stringing at 0.1mm was awful. I followed your advice and reduced the Lift Z (PrusaSlicer) from 0.4 to 0.1. After that my model came out so well you could almost believe it was SLA printed. I was then able to make a silicone mold and cast it in resin and the results were beautiful. I gave some as a gift. Thank you thank you thank you!

ReplyDelete