Strong Tree Supports for Printing Minis

I've been working on a character lately with a bunch of swords, like a whole lot. This model has been especially challenging to print, because those swords stick off of the model at all sorts of odd angles, meaning that they need a lot of support material. I prefer to use Meshmixer Tree Supports for my minis, as the individual trees can snake around complex geometry and they come off pretty easily and leave very little marking where they were connected. That said, there are some challenges that I have to overcome when using those supports.

1: Supporting Supports

Minis often need some fairly long supports, in order to print some weapon or head detail that is high above the printer bed. Tree supports are often leaning at some precarious angle, and I've run into issues where the support will lift slightly as it cools, but due to its length and angle that imperceptible lift gets magnified and causes a nozzle collision.

Minis often need some fairly long supports, in order to print some weapon or head detail that is high above the printer bed. Tree supports are often leaning at some precarious angle, and I've run into issues where the support will lift slightly as it cools, but due to its length and angle that imperceptible lift gets magnified and causes a nozzle collision.

To work around this, I make support for my support. I try to make sure that there's some kind of stabilizing connection for my support trees every 2 cm or so, and I make a special effort to reinforce them around 1 cm above the printer bed. Sometimes, I'll draw additional supports diagonally that will converge into a single tree, and sometimes I'll draw bridges between a few support trees. The key is to make sure that each support tree remains completely stable during the printing process.

2: Strong Fragile Connections

Support material requires a careful balance. It has to connect to the model with enough strength to hold the model up, but it has to be delicate enough to be cleanly removed after the print is completed. I like tree supports for this because the interface between the support and the actual model is generally the diameter of the nozzle itself, meaning that the weakest point should always be that connection. That means that, when I twist the support tree, it should break at that interface and leave my model intact. Should.

This mini is particularly rough on that front. All of those aforementioned swords have annoying things like edges and tips. When I generate the support trees in Meshmixer, I am generating them based on the perfect STL, with infinite resolution. The tip of every odd-angled sword gets its own support tree and everything looks great. But, what's the slicer going to do when it finds that the tip of a sword is something ridiculous, like 1 micron wide? This:

That's the layer preview from Slic3r for this model. You might have to make it bigger to see, but there's a pretty sizable gap between the tip of that sword and the 0.25 mm interface at the top of the support tree. I'm just eyeballing it, but it looks to me like that sword tip is about 5 layers above the top of the support, so it's not going to connect very well. That means that it's probably going to leave a bunch of spaghetti where the end of that sword belongs, all the way until it gets to some other point of contact from which it can actually print the sword. As a reference, this is what a good tree connection looks like:

Notice that the layers for the top of the tree are fully enmeshed with the layers at the back of the sword.

As I work on this model I end up slicing it way more times than I actually print it. At this point, I've only printed 1 version of it (and wow, did I identify a lot of problem areas in that print!), but I've probably sliced it 20+ times. When I slice it, I go into the preview panel and look at how the software is going to instruct the printer to move. I look for conspicuous gaps were the model was too thin and so was abstracted away. I check the spots on the model where I intentionally created overlaps, to ensure that the parts are being printed without a gap (so that they're stronger). Whenever I find an issue, I go back to Blender and work to resolve it, then I export my STL and try again!

7/26/18 Update:

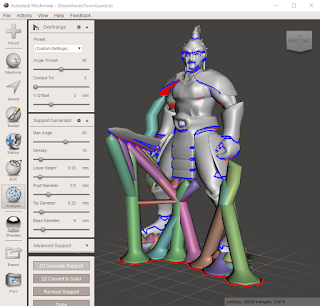

Here's an image of the settings that I like to use in Meshmixer to generate Support Trees. This is for a print that I'm going to run at 0.05 mm with my 0.25 mm nozzle; if you are printing at a different layer height or nozzle size, change those numbers to match what you have!

1: Supporting Supports

Minis often need some fairly long supports, in order to print some weapon or head detail that is high above the printer bed. Tree supports are often leaning at some precarious angle, and I've run into issues where the support will lift slightly as it cools, but due to its length and angle that imperceptible lift gets magnified and causes a nozzle collision.

Minis often need some fairly long supports, in order to print some weapon or head detail that is high above the printer bed. Tree supports are often leaning at some precarious angle, and I've run into issues where the support will lift slightly as it cools, but due to its length and angle that imperceptible lift gets magnified and causes a nozzle collision.To work around this, I make support for my support. I try to make sure that there's some kind of stabilizing connection for my support trees every 2 cm or so, and I make a special effort to reinforce them around 1 cm above the printer bed. Sometimes, I'll draw additional supports diagonally that will converge into a single tree, and sometimes I'll draw bridges between a few support trees. The key is to make sure that each support tree remains completely stable during the printing process.

2: Strong Fragile Connections

Support material requires a careful balance. It has to connect to the model with enough strength to hold the model up, but it has to be delicate enough to be cleanly removed after the print is completed. I like tree supports for this because the interface between the support and the actual model is generally the diameter of the nozzle itself, meaning that the weakest point should always be that connection. That means that, when I twist the support tree, it should break at that interface and leave my model intact. Should.

This mini is particularly rough on that front. All of those aforementioned swords have annoying things like edges and tips. When I generate the support trees in Meshmixer, I am generating them based on the perfect STL, with infinite resolution. The tip of every odd-angled sword gets its own support tree and everything looks great. But, what's the slicer going to do when it finds that the tip of a sword is something ridiculous, like 1 micron wide? This:

That's the layer preview from Slic3r for this model. You might have to make it bigger to see, but there's a pretty sizable gap between the tip of that sword and the 0.25 mm interface at the top of the support tree. I'm just eyeballing it, but it looks to me like that sword tip is about 5 layers above the top of the support, so it's not going to connect very well. That means that it's probably going to leave a bunch of spaghetti where the end of that sword belongs, all the way until it gets to some other point of contact from which it can actually print the sword. As a reference, this is what a good tree connection looks like:

Notice that the layers for the top of the tree are fully enmeshed with the layers at the back of the sword.

As I work on this model I end up slicing it way more times than I actually print it. At this point, I've only printed 1 version of it (and wow, did I identify a lot of problem areas in that print!), but I've probably sliced it 20+ times. When I slice it, I go into the preview panel and look at how the software is going to instruct the printer to move. I look for conspicuous gaps were the model was too thin and so was abstracted away. I check the spots on the model where I intentionally created overlaps, to ensure that the parts are being printed without a gap (so that they're stronger). Whenever I find an issue, I go back to Blender and work to resolve it, then I export my STL and try again!

7/26/18 Update:

Here's an image of the settings that I like to use in Meshmixer to generate Support Trees. This is for a print that I'm going to run at 0.05 mm with my 0.25 mm nozzle; if you are printing at a different layer height or nozzle size, change those numbers to match what you have!

Comments

Post a Comment