Upgrading the Prusa MK3 Nozzle from 0.4 mm to 0.25 mm

I recently upgraded my Prusa MK3's nozzle from the stock 0.4 mm nozzle to a smaller 0.25 mm nozzle to improve my miniature printing results. Prusa has really good instructions for nozzle replacement, which I mostly followed. After some consideration, I decided to only remove the fan mouthpiece, since my intent was to hold the heater block lower than its attached wires anyway (so as to avoid those wires). It worked fine for me, but you should probably stick to the official process unless you feel comfortable with experimenting a bit and possibly replacing something if you break it on accident.

I heated the nozzle to 215 degrees so that I could remove my filament, then brought it up to 255 degrees and went to work. I took out my 17 mm spanner and a 7 mm socket wrench, then prepared for the job. After bracing the heater block with my spanner, I used the socket wrench to slowly unscrew the nozzle (remember, lefty-loosey, righty-tighty, but you're working upside down). There was a bit of an abrupt jerk as I overcame the tension on the nozzle, and after that I just used the socket without the wrench to finish unscrewing the nozzle.

The socket got uncomfortably warm by the end of the process, but it meant that I didn't have to worry about dropping a 255 degree chunk of brass onto my table or floor or foot or anything (and there wasn't enough resistance for it to ratchet, anyway). After I got the old one out, I double-checked that my hot end was still at 255 degrees, then slotted the new nozzle into my socket and put it in. I hand tightened it (via the socket!), then braced the heater block with my spanner once more and gave the nozzle a snugging with my socket wrench. I probably only turned it 45 more degrees here, just until I felt some resistance.

When the nozzle was installed, I turned the temperature back down to 215, then loaded my filament. After it was loaded, I fed another ~40 mm of filament through it, just to make sure that everything was going smoothly, and was then ready to use my new, smaller nozzle on a real print!

I decided to go ahead and print my Scythe Monument, figuring that the Cyrillic characters and little railing would give me a good chance to appreciate the greater details from my new nozzle. I was not expecting what I found, though.

The image on the left is printed at 0.1 mm layers with my original 0.4 mm nozzle. The one on the right is also at 0.1 mm layers, using my new 0.25 mm nozzle. The only change that I made in Slic3r was to the nozzle size, but you can see that it lost a lot of the fine details on the Cyrillic characters. The statue's sword and the rails are both more crisp with the new nozzle, but I'm perplexed as to why the lettering would look so much worse (ignore the apparent difference in top surface quality and layer line visibility - those are both just because I managed to get an unusually in-focus shot of one but not the other).

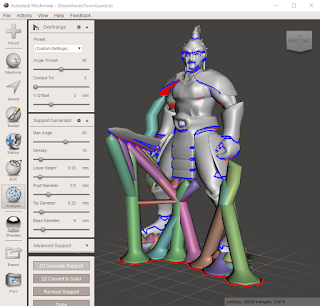

Since I installed this new nozzle in the pursuit of maximum print quality, I decided to go ahead and try it again, but with 0.05 mm layers... and I'm super happy with the results. Check it out, both unpainted and with a light grey primer:

I heated the nozzle to 215 degrees so that I could remove my filament, then brought it up to 255 degrees and went to work. I took out my 17 mm spanner and a 7 mm socket wrench, then prepared for the job. After bracing the heater block with my spanner, I used the socket wrench to slowly unscrew the nozzle (remember, lefty-loosey, righty-tighty, but you're working upside down). There was a bit of an abrupt jerk as I overcame the tension on the nozzle, and after that I just used the socket without the wrench to finish unscrewing the nozzle.

The socket got uncomfortably warm by the end of the process, but it meant that I didn't have to worry about dropping a 255 degree chunk of brass onto my table or floor or foot or anything (and there wasn't enough resistance for it to ratchet, anyway). After I got the old one out, I double-checked that my hot end was still at 255 degrees, then slotted the new nozzle into my socket and put it in. I hand tightened it (via the socket!), then braced the heater block with my spanner once more and gave the nozzle a snugging with my socket wrench. I probably only turned it 45 more degrees here, just until I felt some resistance.

When the nozzle was installed, I turned the temperature back down to 215, then loaded my filament. After it was loaded, I fed another ~40 mm of filament through it, just to make sure that everything was going smoothly, and was then ready to use my new, smaller nozzle on a real print!

I decided to go ahead and print my Scythe Monument, figuring that the Cyrillic characters and little railing would give me a good chance to appreciate the greater details from my new nozzle. I was not expecting what I found, though.

The image on the left is printed at 0.1 mm layers with my original 0.4 mm nozzle. The one on the right is also at 0.1 mm layers, using my new 0.25 mm nozzle. The only change that I made in Slic3r was to the nozzle size, but you can see that it lost a lot of the fine details on the Cyrillic characters. The statue's sword and the rails are both more crisp with the new nozzle, but I'm perplexed as to why the lettering would look so much worse (ignore the apparent difference in top surface quality and layer line visibility - those are both just because I managed to get an unusually in-focus shot of one but not the other).

Since I installed this new nozzle in the pursuit of maximum print quality, I decided to go ahead and try it again, but with 0.05 mm layers... and I'm super happy with the results. Check it out, both unpainted and with a light grey primer:

Comments

Post a Comment