Tweaking PrusaSlicer Support Tree Settings

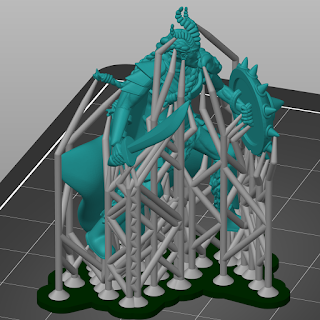

I've continued to play around with PrusaSlicer's support tree generation (for both MSLA and FDM prints), and I'm starting to develop opinions about some of the settings. So, I figured that I'd take a moment to write about the settings that I use to create trees that I like! First, here's a screenshot of the trees that get generated with the default settings (after setting up my custom support points). These are very robust trees, which is great for printing but less great for support removal. When removing tree supports, I've found those diagonal bracings to be especially burdensome, as they make it much more difficult to "cut in to" the model to release the supports from it. Fortunately, we can fix that by tweaking some settings, but you're going to need to go into Expert Mode to get to them all. So, in PrusaSlicer, go to Configuration -> Mode and select Expert to get them to show up.

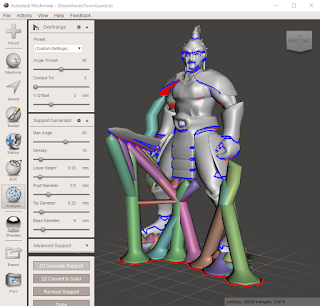

I've continued to play around with PrusaSlicer's support tree generation (for both MSLA and FDM prints), and I'm starting to develop opinions about some of the settings. So, I figured that I'd take a moment to write about the settings that I use to create trees that I like! First, here's a screenshot of the trees that get generated with the default settings (after setting up my custom support points). These are very robust trees, which is great for printing but less great for support removal. When removing tree supports, I've found those diagonal bracings to be especially burdensome, as they make it much more difficult to "cut in to" the model to release the supports from it. Fortunately, we can fix that by tweaking some settings, but you're going to need to go into Expert Mode to get to them all. So, in PrusaSlicer, go to Configuration -> Mode and select Expert to get them to show up. Firstly, we can tweak the Max pillar linking distance setting, potentially turning it all the way down to 0 to completely stop those diagonal braces from forming (that first screenshot has the default value of 10). I don't entirely dislike the braces though, so I've been playing around with using low values instead, so that those braces won't shoot quite so far across the model but will still be there when trees are near enough. There seems to be a certain amount of guess and check that goes into tuning that setting based on the needs of the specific model. I generally find myself setting it somewhere between 0 and 4 mm, depending on how aggressively I want those cross-links to be there. In this second screenshot, I've got it set to 3 and you can see how it's removed those longest braces, but has still kept my support trees strongly interlinked.

Firstly, we can tweak the Max pillar linking distance setting, potentially turning it all the way down to 0 to completely stop those diagonal braces from forming (that first screenshot has the default value of 10). I don't entirely dislike the braces though, so I've been playing around with using low values instead, so that those braces won't shoot quite so far across the model but will still be there when trees are near enough. There seems to be a certain amount of guess and check that goes into tuning that setting based on the needs of the specific model. I generally find myself setting it somewhere between 0 and 4 mm, depending on how aggressively I want those cross-links to be there. In this second screenshot, I've got it set to 3 and you can see how it's removed those longest braces, but has still kept my support trees strongly interlinked.  For my FDM prints, I think that it's more important that they be so strongly interlinked, as you're more likely to get small lateral forces from the printer head moving and you need to prevent any lifting from the support trees warping during cooling. For my MSLA prints, I've been using even lower settings. In fact, when I last printed this model on my SL1, I used a 2 mm linking distance, which generates remarkably different trees. Because there's not a lot of lateral force on my MSLA prints, I figured that I could get away with effectively no diagonal bracing between support trees, which made them very easy to remove. I found myself generally flexing and twisting the trees to remove them (when they're attached to a thick part, like the cape or the main body), and using my flush cutters for the more delicate parts. When using the flush cutters (particularly on the supports for the horns), I made a cut really low down on the tree first, so that the forces generated from the actual removal cut would have somewhere to go besides into the model, and that seemed to work pretty well!

For my FDM prints, I think that it's more important that they be so strongly interlinked, as you're more likely to get small lateral forces from the printer head moving and you need to prevent any lifting from the support trees warping during cooling. For my MSLA prints, I've been using even lower settings. In fact, when I last printed this model on my SL1, I used a 2 mm linking distance, which generates remarkably different trees. Because there's not a lot of lateral force on my MSLA prints, I figured that I could get away with effectively no diagonal bracing between support trees, which made them very easy to remove. I found myself generally flexing and twisting the trees to remove them (when they're attached to a thick part, like the cape or the main body), and using my flush cutters for the more delicate parts. When using the flush cutters (particularly on the supports for the horns), I made a cut really low down on the tree first, so that the forces generated from the actual removal cut would have somewhere to go besides into the model, and that seemed to work pretty well! There is one other setting that I like to tweak: the Critical angle. This affects the angle at which those trees will shoot out their branches. It defaults to 45 degrees which, while perfectly printable, leads to some longer angled runs than I like (especially for my FDM prints). I've been adjusting it to 55 degrees and am much happier with the trees that it generates (and this is the print that I actually ran). The long angled support that used to go over her cape to the tip of her braid is now at a less dramatic angle, coming off the same tree as the base of her sword. Also, the steeper angle results in fewer cross-braces between the trees. If you look at the previous 45 degree image, there are 4 triangles going down between the braces on the shield, but this new one only has 2.5.

There is one other setting that I like to tweak: the Critical angle. This affects the angle at which those trees will shoot out their branches. It defaults to 45 degrees which, while perfectly printable, leads to some longer angled runs than I like (especially for my FDM prints). I've been adjusting it to 55 degrees and am much happier with the trees that it generates (and this is the print that I actually ran). The long angled support that used to go over her cape to the tip of her braid is now at a less dramatic angle, coming off the same tree as the base of her sword. Also, the steeper angle results in fewer cross-braces between the trees. If you look at the previous 45 degree image, there are 4 triangles going down between the braces on the shield, but this new one only has 2.5. If anyone's curious, here's a screenshot with the 3 mm FDM style links and a 55 degree critical angle (so compare it to the image a few back, not the immediately preceding ones). The reduction in bracing density is really noticeable here, where the longer pillar linking distance causes more braces to be drawn. Most of the same pillars are still being interlinked (although there are some pillar differences, like on the far left), there are just fewer of those links being drawn now. Also, while a 45 degree overhang is absolutely printable on an FDM printer, that can get a bit dicey for a support tree because of PLA's tendency to lift when it cools (and I've heard that ABS is even worse). The 55 degree supports give you a bit more safety margin over those longer runs.

If anyone's curious, here's a screenshot with the 3 mm FDM style links and a 55 degree critical angle (so compare it to the image a few back, not the immediately preceding ones). The reduction in bracing density is really noticeable here, where the longer pillar linking distance causes more braces to be drawn. Most of the same pillars are still being interlinked (although there are some pillar differences, like on the far left), there are just fewer of those links being drawn now. Also, while a 45 degree overhang is absolutely printable on an FDM printer, that can get a bit dicey for a support tree because of PLA's tendency to lift when it cools (and I've heard that ABS is even worse). The 55 degree supports give you a bit more safety margin over those longer runs.Well, that's what I've been playing around with lately in regards to my slicer settings for support trees. I know that I've learned a lot and I hope you have too!

Great post. This is exactly what I was looking for as I'm trying to print some figurines on my FDM printer using the tree supports in PrusaSlicer. What about the stem diameter? Do you play around with that at all?

ReplyDeleteI don't see a "stem diameter" setting in the "settings" tab, but I think "Support Pillar Diameter" might be the same thing. I set that to 2 mm for my FDM prints, although you could probably get away with making them a bit smaller.

Delete