How To Use Pre-Supported .3mf Files

As I've written about a few times, I've been using PrusaSlicer's SLA tree supports for my FDM prints... and while it's not perfect, I'm happy enough with the workflow that I haven't wanted to change it! One of my favorite aspects of using PrusaSlicer's tree supports is that I can design them, then save the supported .3mf file, and then other people can open that file and tweak the trees. That's really important because different printers have different capabilities, and when you size a support tree to work with a 0.25 mm nozzle, it's not always going to provide adequate support for a 0.4 mm nozzle print (and won't take advantage of the smaller interfaces you could get from a 0.15 mm nozzle!). The .3mf format allows people to tweak those settings for themselves, while using the same basic support design!

This adaptability means that I can share my pre-supported .3mf files with my patrons, and there's a reasonable chance that they'll be able to use it to get a successful print (once they have an appropriate profile configured on their system). If they need to make changes, the support points are fully adjustable, unlike the older supported STLs that I used to generate through Meshmixer. All of this is great in theory... but it's not worth anything without instructions for how to actually do it! So, today we're going to talk about how you can use one of those .3mf files to generate a supported STL that you can then slice in whatever slicer you like!

First, you'll need to install PrusaSlicer (there are probably other slicers that can use .3mf files, but this is the one that I use and it's what I'll use for these instructions).

When you open PrusaSlicer for the first time, it'll prompt you with a Configuration Wizard (if you need to open it again, you can go to the Configuration menu, then select Configuration Wizard). First, you'll need to select a printer or two. As a bare minimum, in the Prusa MSLA section, select the Original Prusa SL1. That will allow you to take the .3mf file and generate a supported .STL from it. If you want to use PrusaSlicer to actually slice the supported .STL file, you'll also want to select whatever printer you actually have. If you're going to use it for Slicing, continue through the Wizard and select your desired Filaments, otherwise you can just hit Finish.

If you installed anything other than the Original Prusa SL1, change over to that printer by going to the Printer dropdown on the right side and selecting Original Prusa SL1. We need to use this printer profile in PrusaSlicer because tree supports are only officially supported for MSLA printing. While I agree that they work much better with MSLA prints (it felt like the support trees almost wanted to fall right off of my resin prints), they can still work great for FDM prints (although you'll need your snippers to remove them)!

Now that you've got PrusaSlicer set up, you can open a .3mf file! Go to File -> Open Project and browse to the .3mf that you want to print. That file will already have my FDM Supports profile loaded up, so if you're using a printer with a 0.25 mm nozzle, you (hopefully) won't need to tweak anything. Otherwise, you'll want to go to the Print Settings tab and optimize the settings in the Supports section (make sure to click the Expert button on the top right to see all of the settings). If you want to read about my experiments with those settings, you should check out those articles that I linked earlier, as there's a lot to tweak there!

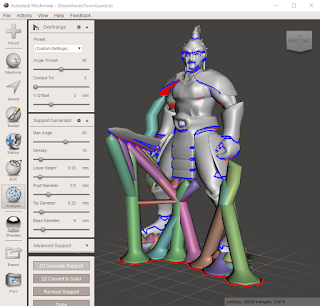

Once you're happy with your tree settings, you can either hit the Slice Now button on the bottom right to use my support points or press the SLA Support Points icon on the left (it's the lowest icon in that row) to change them (make sure to apply any changes that you make!). Either way, you'll cause PrusaSlicer to calculate the support trees, which is what you'll want. Once those trees are generated, you can go to File -> Export -> Export Plate as STL Including Supports... to get the whole thing as a single STL file! Once you've got that exported, you can load that up in your favorite slicer and you're probably good to go...

Probably. There's an annoying bug with those supports, where they sometimes generate geometry below the surface of the printer bed. This is a problem when you convert the supported model to an STL, because the "printer bed" isn't a thing as far as that file format is concerned. Typically, the lowest point on the model will be placed on the bed... and in this case, that's that annoying dome that was generated on the bottom of a support tree. When this happens, you should use your slicer's Cut functionality (the 3rd icon from the bottom, in PrusaSlicer) to lop off the bottom and get that 1-layer thick pad directly onto your printer bed. In PrusaSlicer, I enable Keep upper part and disable Keep lower part and Rotate lower part upwards, then I futz around with the Z height until I'm just removing the undesired dome.

Hi, Thanks for your post. Regarding the "bug" you mentioned in the end of the post, there is a selection in PursaSlicer, when creating supports for .3mf model. On right side under Supports option there is Pad option. Selecting "Below object" will create supportes as shown on the picture, while "Around object" will do it in a correct way, not creating supports under the model.

ReplyDeleteThanks for the feedback, but I am using "Around Object" (I see that it's hard to tell in those screenshots; Blogger used to let them grow to full resolution on click, but that seems to have changed) as my Pad setting. When selecting "Below Object" the object is lifted 5 mm so that supports can go from the pad to the bottom of the object. When possible, I like to have my model's feet on the build plate so that they'll be truly flat, so I stick with the "Around Object" option. The "bug" seems to occur when a support tree is short and angled; PrusaSlicer doesn't generate the usual Support Base and we get that clipped geometry instead.

DeleteOk, I fixed the screenshots in this post so that they can display at full resolution. If anyone else is looking to fix this, I ended up editing the post's HTML code directly using the technique discussed in this support thread: https://support.google.com/blogger/thread/48602861?hl=en

DeleteOk, now I can see what is the real issue :)

Delete